The Fourth Industrial Revolution is data-driven. And a primary reason for this is the rise of the internet of things (IoT). Connected devices from the consumer level to the industrial are creating—and consuming—more data than ever before. Last year, IoT devices outnumbered the world’s population for the first time, and by 2021, Gartner predicts that one million new IoT devices will be purchased every hour.

In this Extreme Data Economy, businesses, governments, and organizations need to analyze and react to IoT data simultaneously, in real time. This requires continuous analysis of streaming and historical data, location analysis, and predictive analytics using AI and machine learning.

To overcome these challenges and attain the full potential of the IoT across industries, governments and businesses alike need to consider how these devices—and their data—can make the most significant, positive impact on people’s lives.

Let’s consider a few examples of IoT data analysis that are tackling the challenge head on.

As the world’s population grows, governments and businesses both realize that we must better manage finite natural resources. We are working with an energy exploration company to discover and determine the viability of energy resources much more efficiently. Before this, they could visualize and analyze a maximum of 9 million sensor data points.

Now, they get an MRI-like image of a subset of the earth visualizing 90 billion sensor data points instantaneously, instead of in days or weeks. They can now arm their geologists and data scientists to optimize resource exploration and extraction. Geologists can consider how changing a variable impacts resource extraction from a given reservoir, for example—a process that used to take days or weeks.

Higher density datasets offer a higher degree of assurance that these predictions are actually accurate, mitigating risk to the environment as well as to the bottom line. We’re excited that this technology can make a significant impact across the energy sector, from traditional to renewable resources.

In fact, the World Economic Forum’s Center for the Fourth Industrial Revolution is working with IoT initiatives in Denmark that are creating incredible societal efficiencies. An Accenture study already suggests that the integration of IoT data in key sectors in Denmark could deliver $80 billion in value. This is particularly notable given that Denmark is a country with only 5.7 million people and a GDP of about $330 billion.

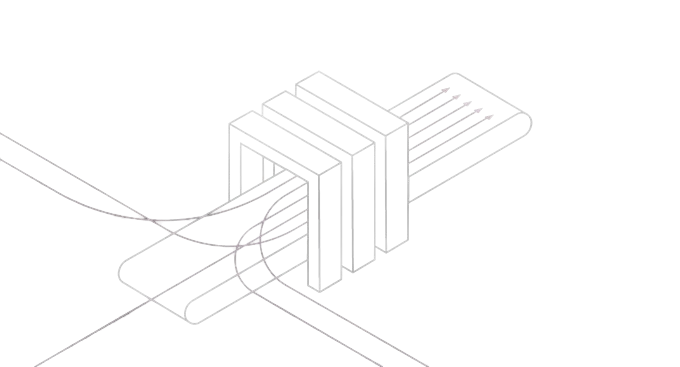

The Testbed in Aarhus for Precision Positioning and Autonomous Systems (TAPAS) is a science and research platform that was set up to figure out if an improved urban geodetic (coordinate system) infrastructure could allow municipalities to make use of high accuracy positioning through GNSS (Global Navigation Satellite Systems). The goal is to provide extremely accurate, real-time, dynamic positioning. Dynamic data pose specific problems, particularly because of their real-time nature: they must be generated, validated, and made available to the user’s equipment without delay, and the platform makes it possible for the user and an object in motion to reach a dynamic position with the precision of 1cm3.

The testbed is an innovation platform in the city and port of Aarhus (the second-largest city in Denmark), consisting of a physical network of 11 densely placed reference stations that correct the inherent deviations and errors of satellite (GNSS) signals in order to determine a precise position. The platform is a joint initiative of the Agency for Data Supply and Efficiency, the Technical University of Denmark, and The City of Aarhus.

This incredible IoT platform could be used by the public sector to test smart city initiatives or to develop aids for the visually impaired to navigate the city, for example. Or it could be used by the private sector, or a public-private partnership, to test driverless cars or drones because they can tap into precise positioning of objects in motion. The technology is publicly available, so the potential is unlimited.

Another relevant example of IoT data at work: a government customer that makes daily deliveries to more than 154 million addresses using several hundred thousand vehicles and employees. They knew they needed to improve their end-to-end business process performance while reducing costs at the same time. They turned to us to create efficiencies based on visual near-real-time data coming from 200,000+ devices emitting location once every minute (more than a quarter billion events captured and analyzed daily).

Kinetica’s Active Analytics Platform was used to visualize geospatial data (routes, delivery points, and collection point data) so that dispatchers could efficiently plan and graphically view employee territory assignments. They were able to make the best use of routes and to find inefficiencies such as overlapping coverage of assigned areas, uncovered areas, and distribution bottlenecks. They were also able to improve contingency planning if a carrier was unable to deliver to assigned routes and use their work force more efficiently by aggregating point-to-point carrier performance data.

By determining optimal geographical boundaries, the delivery service was able to reduce unnecessary transport costs. Optimizing routes resulted in on-time deliveries, fewer trucks handling a greater number of deliveries, and more precise delivery windows. Improving end-to-end business process performance while reducing costs requires the ability to make fast business decisions based on live data. But doing so saves millions of dollars, and ensures safer, on-time deliveries.

It’s clear that the IoT can bring incredible societal as well as financial return on investment, but we have to begin making those investments now so that we can tap into the huge potential of this technology, for both business and society, as soon as possible.

Nima is the co-founder and CTO of Kinetica. This article was originally published in Forbes.